In today’s fast-moving supply chains, packaging isn’t just about presentation — it’s about protection. ISTA Testing is the global standard for evaluating whether your packaging can withstand the rigors of real-world transport. From fragile electronics to heavy-duty equipment, ISTA Testing helps manufacturers, retailers, and logistics providers ensure their packaging performs as intended from factory to customer.

What does ISTA stand for?

ISTA stands for the International Safe Transit Association, a globally recognised organization that develops testing protocols to verify the strength and durability of packaging. These standardised procedures allow companies to evaluate how their packages hold up under various transit conditions — including drops, vibrations, compression, and environmental changes.

What is an ISTA Test?

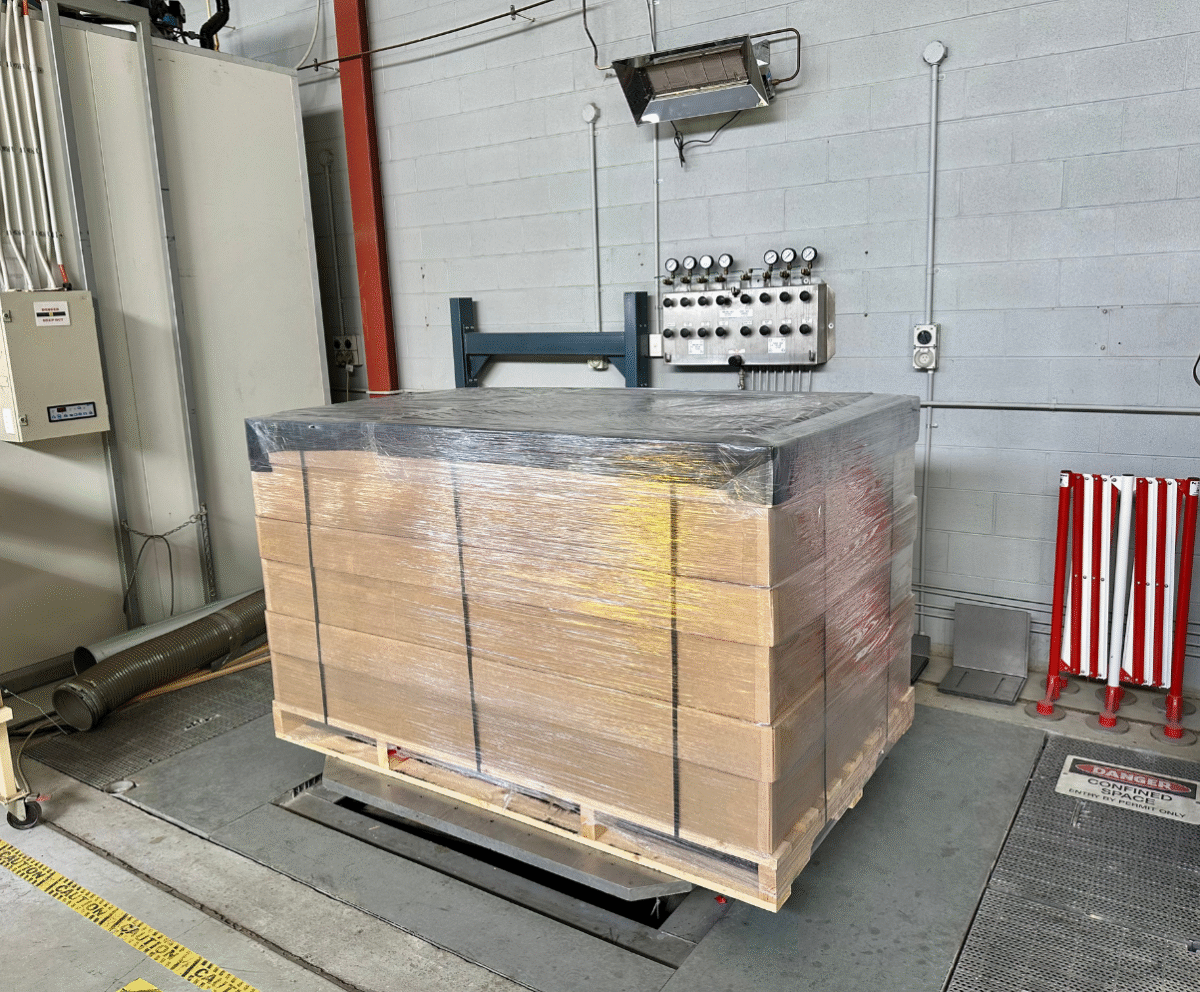

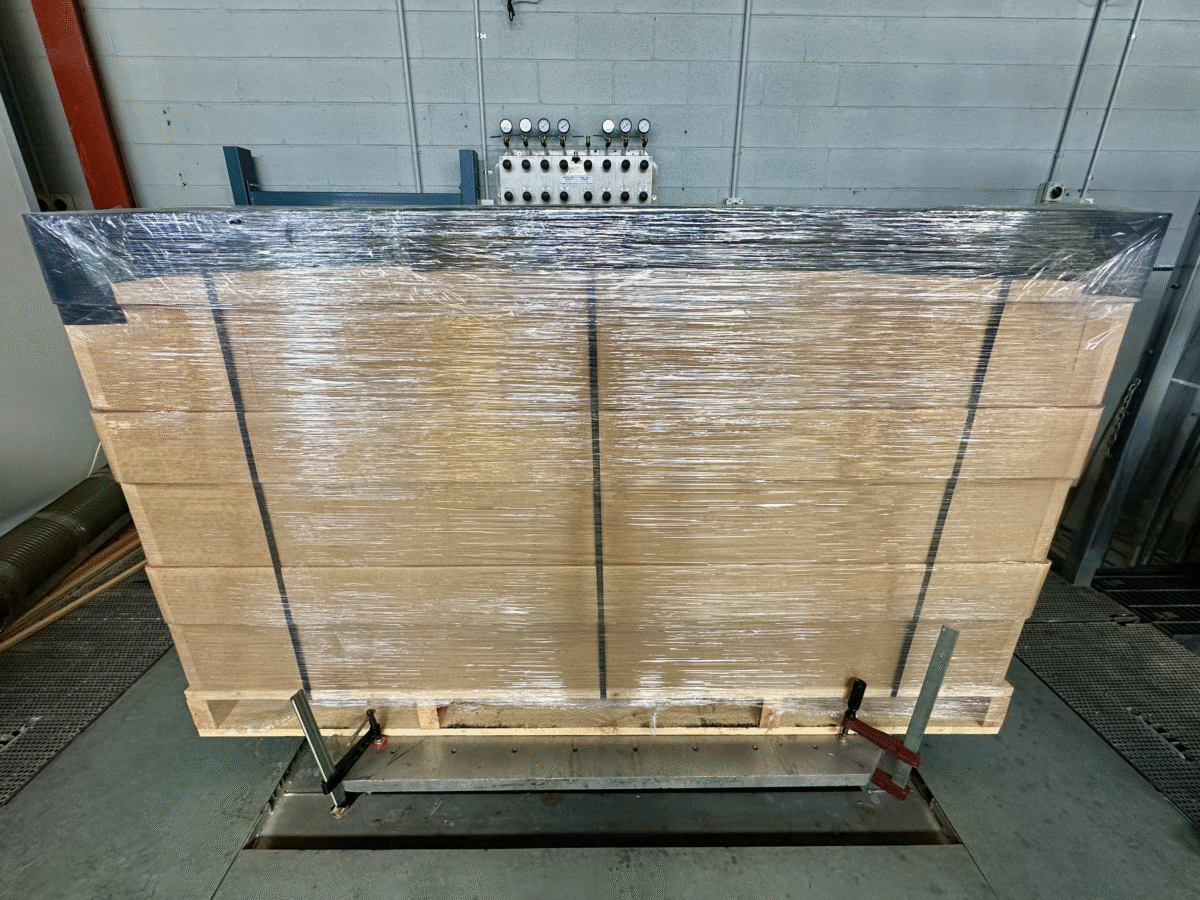

An ISTA Test simulates the physical and environmental stresses a package might encounter during handling, storage, and shipping. The goal is to determine if the packaging effectively protects its contents from damage throughout distribution. ISTA Testing services are carried out by accredited laboratories that replicate these transit hazards under controlled conditions. Once testing is complete, the lab provides a detailed report or certificate verifying that the package meets ISTA standards.

The different levels of ISTA Testing

ISTA offers several levels of testing, each representing a different type of simulation and complexity:

- ISTA Series 1 – Non-Simulation Integrity Tests:

Basic tests to assess packaging strength and product protection without replicating specific transportation conditions. Ideal for preliminary design validation.

- ISTA Series 2 – Partial Simulation Tests:

Combine simple handling tests with partial environmental simulations to evaluate packaging under mixed conditions.

- ISTA Series 3 – General Simulation Tests:

Simulate a broad range of transport environments, including vibration, shock, and compression, for a realistic view of packaging performance.

- ISTA Series 4 – Enhanced Simulation Tests:

Tailored simulations based on real-world data and specific distribution environments.

- ISTA Series 6 – Member Performance Tests (e.g., Amazon, FedEx):

Custom tests developed for major distributors and eCommerce partners to meet their unique shipping requirements.

These levels ensure that an ISTA Test can be customized to fit the actual challenges your packaging will face in transit.

How to Get an ISTA Certificate

To obtain an ISTA Certificate, your packaging must be tested at an accredited ISTA Testing laboratory. The lab will perform the required test series, analyse the results, and issue a report confirming compliance. If the package passes, the company receives an ISTA certification demonstrating that the packaging meets international standards for safe transport.

How Long Does ISTA Certification Last?

An ISTA certification does not technically expire, but it’s best practice to retest packaging whenever materials, design, or shipping conditions change. Regular testing ensures ongoing compliance with updated standards and real-world transport demands.

How Long Does the Process Take?

The ISTA Testing process typically takes between one and three weeks, depending on test complexity, lab capacity, and the number of packaging samples required. For ISTA 6 or custom protocols, additional time may be needed for test setup and reporting.

ISTA Testing provides peace of mind that your packaging isn’t just well-designed — it’s proven to protect. By investing in certified testing services, you safeguard your products, reduce damage rates, and build trust throughout your supply chain.